- Innovation

- Sep 11, 2025

- 0

Smart Dyeing: How AI Cuts Waste in Textiles

In conventional dyeing, colors are applied to wet fabrics—with unpredictable shifts occurring during drying. These non-linear color changes often lead to dyeing errors that can only be detected late in the process. As Jasper explains, by the time these mistakes surface, entire batches may need re-dyeing, contributing to massive material and resource waste.

To tackle this issue, Jasper and his team developed five machine learning models to map the complex transition between wet and dry color states. Their neural network stood out with exceptional accuracy: a CIEDE2000 error as low as 0.01 and a median error of 0.7, well below the industry’s typical acceptability threshold of 0.8–1.0. In comparison, traditional methods produced errors up to 13.8—demonstrating the vast improvements possible with machine learning guidance.

This AI-driven prediction enables manufacturers to identify and correct color deviations early, reducing re-runs, minimizing resource waste, and saving time and cost across production workflows.

Machine learning isn’t only enhancing color accuracy. Numerous textile manufacturers are leveraging AI and ML for real-time monitoring, resource optimization, and predictive maintenance. AI systems analyze data from dyeing equipment to ensure consistent temperature, chemical balance, and application uniformity—drastically improving efficiency and reducing downtime.

By using models trained on historical data, AI algorithms accurately forecast energy and water usage and optimize formulations to avoid overuse. Coupled with automation, this enables dramatic reductions in chemical and resource consumption, supporting sustainable production standards.

Given the environmental footprint of traditional dyeing—particularly its high water, energy, and chemical demands—machine learning models offer a powerful solution. With improved prediction and real-time response, factories can significantly reduce waste, lower carbon emissions, and limit harmful chemical runoff. These practices align with ethical and regulatory demands across global markets.

Moreover, optimizing dyeing operations through AI translates into business advantages: reduced material costs, fewer quality control failures, faster turnarounds, and higher product consistency. This positions brands and manufacturers to deliver better value while meeting customer and regulatory expectations for sustainability.

While promising, widespread adoption of machine learning in textile dyeing is still emerging. Challenges include the need for robust data collection, integration with existing systems, and investment in AI-ready infrastructure. But as textile makers continue to digitize operations and gather production data, the path is clear for scalable, intelligent dyeing processes that deliver reliability and resource efficiency.

At ITG Group, we recognize the transformative potential of machine learning in textile dyeing. While we continue monitoring these innovations, our goal is to help our clients stay ahead through efficient, high-quality textile production. By offering machinery, spare parts, and advisory support tailored to each of our clients needs, we aim to empower them to produce fabrics that lead the market. We’re your commercial ally in the textile industry, committed to weaving success together.

- Textile industry

- Aug 13, 2025

- 0

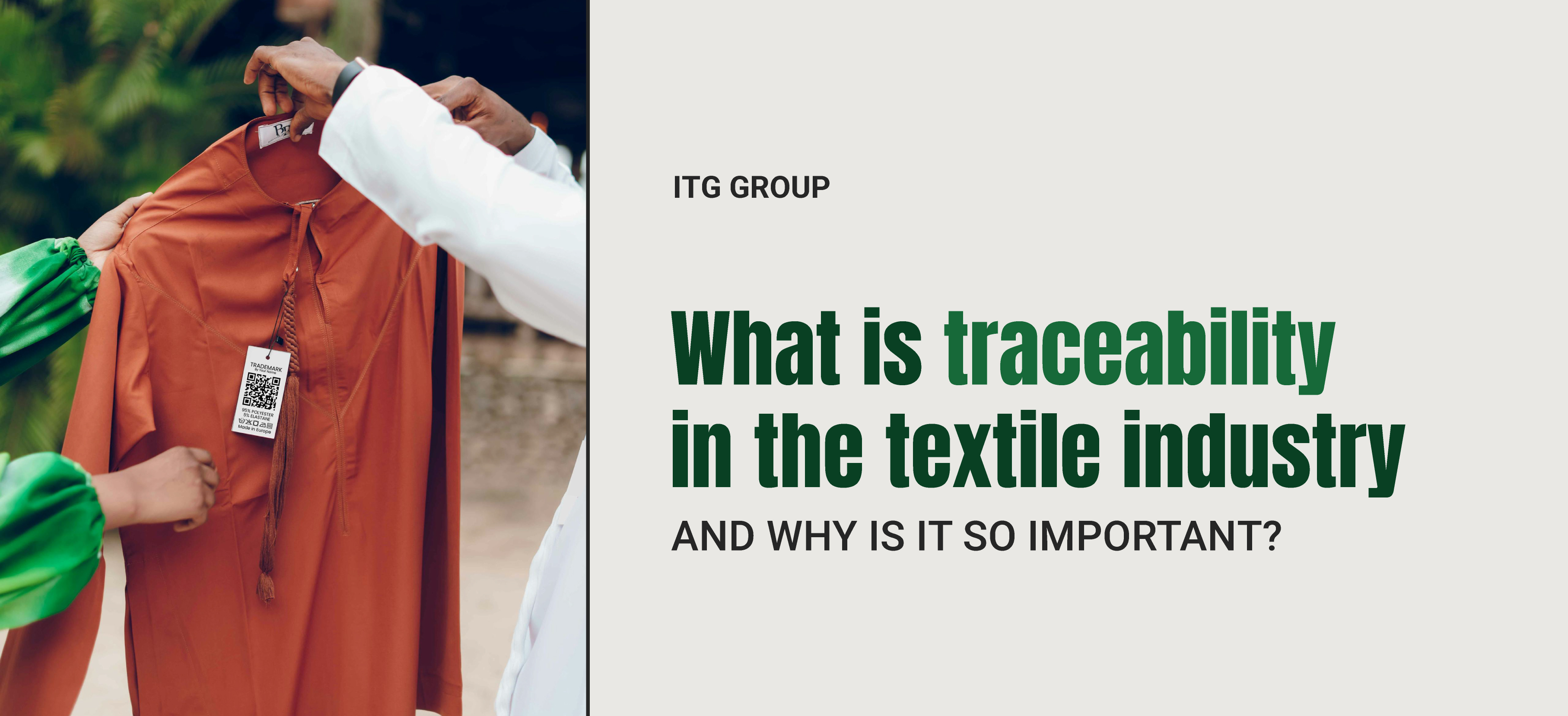

What is traceability in the textile industry and why is it so important?

Textile traceability refers to the ability to track the journey of a garment or other product from its origin—the raw material—to its final destination: the consumer or recycling. This system documents each stage of the production process (such as spinning, weaving, dyeing, finishing, and distribution), allowing us to know how, when, and where it was manufactured, with what materials, and under what conditions.

The importance of traceability

Transparency and trust

In an era where consumers demand to know the origins and impact of what they buy, traceability offers security and credibility. When a brand can demonstrate that its products respect labor rights and environmental criteria, it generates trust and loyalty.

Social and environmental responsibility

Traceability ensures that good practices are followed throughout the chain, preventing labor exploitation and minimizing pollution. It also facilitates recycling, as knowing the materials used is essential for separating and reusing garments correctly.

Quality and safety

An effective system allows for the rapid detection and isolation of faults, such as dyeing defects or composition problems, improving quality control. It also helps to comply with strict regulations, such as REACH in the European Union.

Operational efficiency

Recording each batch and movement reduces errors, delays fewer processes, and optimizes the supply chain.

Steps to implement traceability in textiles

- Product or batch identification: assign unique codes such as RFID or QR codes from raw material to final product

- Process recording: document each stage of the process (dyeing, cutting, manufacturing), including date, location, and operator data.

- Use of technology: integrate blockchain for immutable records, IoT and RFID for real-time monitoring, and ERP software to consolidate data.

- Information exchange: ensure compatibility between systems to share data between suppliers, manufacturers, and distributors.

Faced with social, regulatory, and commercial pressure, large groups such as Kering, H&M, and LVMH have already implemented tools such as the blockchain-based AURA platform to track their products. Initiatives such as Fashion Revolution promote transparency in manufacturing, while campaigns such as Clean Clothes push for fair working conditions. Certifications (e.g., GOTS or Global Recycled Standard) have also gained relevance by supporting brands real commitment.

Traceability in the textile industry is much more than a documentary exercise: it represents transparency, environmental responsibility, safety, and efficiency. To become the norm, the use of technologies such as blockchain, IoT, RFID, and integrated management platforms, together with global standards and consumer pressure, is essential. Only then will truly ethical and sustainable fashion be achieved.

ITG Group recognizes that the products generated by its customers are distinguished by their quality, and therefore understands the importance of supporting that value with increasingly transparent processes. Traceability not only allows the origin and conditions under which a textile was produced to be demonstrated, but also strengthens confidence in its excellence. That is why ITG Group accompanies its customers on the path toward a more traceable, transparent industry that is prepared for the demands of todays consumers. We are your business partner in the textile industry.

Information obtained from:

https://www.vogue.mx/moda/articulo/trazabilidad-textil-que-es-y-como-funciona

- Textile industry

- Jul 04, 2025

- 0

How do international treaties affect the textile trade?

The international textile trade is one of the most dynamic in the world and is deeply influenced by multilateral and bilateral agreements that define the rules of the game between countries.

Free trade agreements (FTAs), customs unions, and other regulatory frameworks not only affect tariffs but also technical standards, origin requirements, and sustainability policies. For companies in the sector, understanding these agreements is key to competing efficiently and expanding markets.

1. Reduction of tariffs and logistics costs

One of the most obvious impacts of the treaties is the reduction or elimination of tariffs on the import and export of textile products. This allows manufacturers to access cheaper raw materials and place their products in new markets with greater competitiveness. For example, countries such as Mexico, through the USMCA, have achieved significant tariff advantages in trade with the US and Canada.

2. Rules of origin: opportunities and restrictions

Treaties often include rules of origin that determine when a product qualifies for the benefits of the agreement. In the case of textiles, this may include the type of yarn, the country where the dyeing or manufacturing takes place. These rules are decisive for accessing tariff preferences, but they can also limit operations when raw materials come from third countries outside the treaty.

3. Access to new markets

Treaties also open up opportunities for geographical expansion for manufacturers and distributors. Textile companies that were previously restricted to their local markets can now export products under more favorable conditions. This has been key to the growth of many textile SMEs in Latin America, Southeast Asia, and Africa.

4. Technical standards and sustainability

In addition to trade, many modern treaties include clauses on sustainability, working conditions, and technical standards. This means that companies must adapt their processes to specific regulations if they wish to operate under these agreements. Although this may involve an initial investment, it also represents an opportunity for modernization and differentiation.

5. Protection against anti-dumping measures and non-tariff barriers

Treaties also offer dispute resolution mechanisms and protection against unfair trade barriers, such as dumping practices or restrictive quotas. This provides greater legal certainty for exporters and allows for long-term planning without regulatory surprises.

In conclusion, international treaties are not just a legal framework: they are strategic tools that can impulse or slow down the development of the textile sector, depending on how they are understood and used. For companies such as ITG Group, being aware of current agreements and their implications is part of the commitment to offer competitive, accessible solutions adapted to each market.

- Textile industry

- Jun 16, 2025

- 0

Ahead of the Curve: PUMA’s Sustainability Win

In a significant move for the global apparel industry, German sportswear brand PUMA has surpassed its 2025 goal of sourcing 90% of its products from more sustainable materials—an achievement reached a full year ahead of schedule. By the end of 2024, 9 out of 10 PUMA products, including apparel, footwear, and accessories, were made using materials such as recycled polyester and cotton sourced through the Better Cotton Initiative (BCI).

This milestone is part of PUMA’s broader Forever Better sustainability strategy, which prioritizes environmental responsibility and ethical practices across its value chain. While the shift to eco-materials is a major achievement, it’s only one part of the brand’s ambitious commitment to sustainability.

In parallel with its environmental goals, PUMA has also made strides in strengthening human rights and fair labor practices. The company has increased its engagement with suppliers to improve working conditions, supported efforts to ensure freedom of association, and worked to increase wages in key sourcing regions. According to PUMA, the company has been actively collaborating with factories to assess and improve wage structures, with the goal of going beyond minimum wage compliance and helping employees move toward living wages.

This twofold commitment—to the planet and to the people who make the products—demonstrates a holistic approach to sustainability. It’s not only about what materials go into a product, but also about how and by whom those products are made. PUMA’s success serves as a clear example of what can be accomplished when companies set ambitious goals and back them with meaningful action and strong partnerships across the supply chain.

The achievement is also a powerful reminder of the impact that supplier relationships can have. PUMA’s ability to surpass its sustainability targets is deeply connected to its work with sourcing partners who share the brand’s values and long-term vision.

At ITG Group, we are inspired by milestones like these. We remain committed to our own goals—and those of our clients—to build strong, forward-thinking companies that lead in the textile industry. Part of that mission includes keeping our community informed with the most relevant news, insights, and innovations shaping the future of fashion and textiles.

Information obtained from:

Spanish

Spanish

English

English

Italian

Italian

Portuguese

Portuguese

French

French